Auto Weighing & Batching Systems

Description

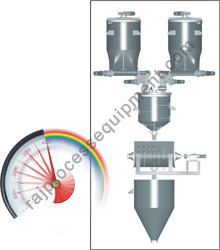

Auto-Weighing and Batching System, as the name suggests, is used for precise weighing of multiple products to prepare a batch which is then further mixed and then packed.

The system can be used for Powders, Cakes and Liquids. The system is a completely pre-engineered system with instruments provided for automation. Fully automatic and semi-automatic versions of this system are available.

Construction and Operation

The system consists of Multiple Storage Hoppers, with or without Agitators, depending upon the nature of product. These Storage Hoppers are fitted with coarse and fine screws at the bottom.

The screw feeders discharge the material into the Weighing Hopper, which is placed on load cells.

Pre- determined quantity of material from each Storage Hopper is fed to the Weighing Hopper.

The batch controller controls the starting and stopping of the coarse and fine screws as per the program and quantity given in it.

Once the required quantity of material is fed to the Weighing Hopper, the bottom valve is opened to discharge the material to mixer.

The mixer can be any type like, Ribbon Blender, Cone Screw Mixer, Agitated Vessel etc. Once the Weighing Hopper is empty, the next batching cycle starts. The system can be programmed for any number of batching cycles.

Features

- Minimum handling of product.

- Uniform product quality.

- Weighing accuracies up to 0.1 percent.

- High mixing accuracy and minimum mixer idle time.

- Continuous and automatic operation.

- No product loss.

- Low floor space requirement.

The system is made to suit the specific requirement of the customer as regards batch size, number of products to be mixed and their quantities etc. The material of construction of product contact parts is either carbon steel or stainless steel, depending upon product nature.

Application

- Pharmaceutical

- Food

- Chemical

- Fertiliser

- Ceramic

- Mineral

- Biochemicals

- Sand

- Fluxes, etc.

Features

- Fully automatic system to ensure smooth and easy operation.

- Sterile construction of equipment to maintain high hygiene level.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- Complete sanitary design with CIP system.

- PLC controlled SCADA operated system.

Services

- Turnkey Plants.

- Manufacturing & Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management.

- Commissioning and Training.