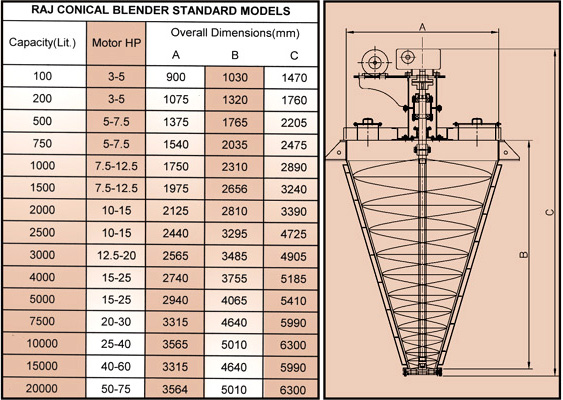

Conical Blender

Conical blender consists of a conical vessel with a double start helix ribbon mounted on central shaft. This type of blender is used for mixing, granulation and homogenizing applications. It handles a range of applications from all types of powders including free flowing to cohesive and moist powders, bulk dry materials to wet cakes and slurries.

Mixing time depends on the ribbon speed. The rotating central agitator shaft does not have bottom bearing support thereby eliminating any dead spots or difficult areas to clean and there is no possibility of product contamination.

Discharge of the product is fast and simple as the bottom is fully open.

Various design options available are :

- Models with single or double helix.

- Capacities from 20 to 25000 litres.

- Cutting rotors for breaking of agglomerates.

- Liquid addition provisions. Heating / Cooling jacket or limpet with insulation.

Features of RAJ Conical Blenders :

Raj Conical Blenders are best suited for mixing, granulation & homogenising batch process. It handles a range of applications from all types of powders including free flowing to cohesive & moist powders, bulk dry materials to wet cakes & slurries.

Raj Conical Blenders are very sturdy and robust. They consists of a conical vessel with dished /flat head. The central agitator shaft is driven from top end with gear reducer.

A double helical ribbon agitator in the vessel moves the product upward along the outer wall and releases it downward into cavities developed in the middle, simultaneously material is horizontally distributed by the mixing arm and is optimally homogenised.

Mixing time depends on the agitator speed. In general mixing time is three to four times shorter than the mixers working with a rotating screw. The drive and bearings are kept outside of the vessel, no gears or seals in the product compartment. The rotating central agitator shaft does not have bottom bearing support there by eliminating any dead spots or difficult areas to clean and there is no danger of product contamination. Discharge of the product is fast and simple as full bore open.

Design options

- Models with single or double helix.

- Net capacities for 20 to 25000 litres.

- Various Material and surface treatment available depending upon product characteristics.

- Cutting rotors for breaking down ofagglomerates.

- Liquid addition by ISP system.

- Heating Cooling jackets with insulation.

Features

- Material are mixed to highest levels of accuracy even if some of the components are present in minor quantity

- It has flexible working capacity to 10 100% of filling rate

- Disintegration of agglomerates most often without additional tools

- Easy to clean

- Dust-and ex-proof models

- Space saving construction

- Various shaft sealing system

- Product discharge through gate, isem, ball segment or ball valve

- No danger of product contamination by lubricants.

Features

- Fully automatic system to ensure smooth and easy operation.

- Sterile construction of equipment to maintain high hygiene level.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- Complete sanitary design with CIP system.

- PLC controlled SCADA operated system.

Services

- Turnkey Plants.

- Manufacturing & Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management.

- Commissioning and Training.