Food Process Guar Gum Plant in Pune

Depending upon the requirement of end product various processing techniques are used. In India the commercial production of Guar gum is normally undertaken by using process of roasting, differential attrition, sieving and polishing.

Guar gum is an agrochemical processed from the plant called cluster bean. It has various uses in different industries. It is used as an additive in food, pharmaceutical, paper, textile, explosive, cosmetic industry, etc. It is mainly used as a thickening agent. One of the major uses of guar gum is in the medical field and it is used to treat many ailments and is part of various medicines.

The stage wise process of manufacturing

food grade guar gum is as under. It is very

important to select guar split in this process.

The split will be screened to clean and then it

will be soaked to prehydrate in a double cone

mixer/Washing conveyor. Prehydrating

stage is very important in the process as it

derives the rate of hydration of the final

product.

The soaked splits, which has reasonably

high moisture content, will be passed

through Flaker. The flaked guar split will be

predried in duct dryer. The dried guar flake

will be ground to desired particle size in

ultrafine grinder followed by drying of the

material in flash dryer. The powder will be

screened through rotary screens to deliver

required particle size. The oversize particles

will be either recycled to main Ultrafine or

reground in separate regrind plant, as per

viscosity requirement.

This stage helps to reduce the load at the

grinder. The soaked splits are difficult to

grind. Direct grinding generates more heat in

the grinder which is not desired in the

process as it results in insoluble or reduced

hydration of the product. Through heating,

grinding & polishing process the husk is

separated from the endosperm halves and

the refined Guar Gum split are obtained.

Through grinding process the refined Guar

split are then treated and converted into

powder.

During the split manufacturing process, husk

& germ are obtained which are used as a

cattle feed as they are rich in protein. It is

widely sold in the international market as

"Guar Meal" and has contents of "Oil &

Albuminoids". These contents are about

50% in germ whereas it is about 25% in

husks. Quality of the food grade guar gum

powder is defined from its particle size, rate

of hydration and the microbial in it. E412 guar

gum is an important natural food supplement

with high nutritional value.

How does Guar Gum plant work?

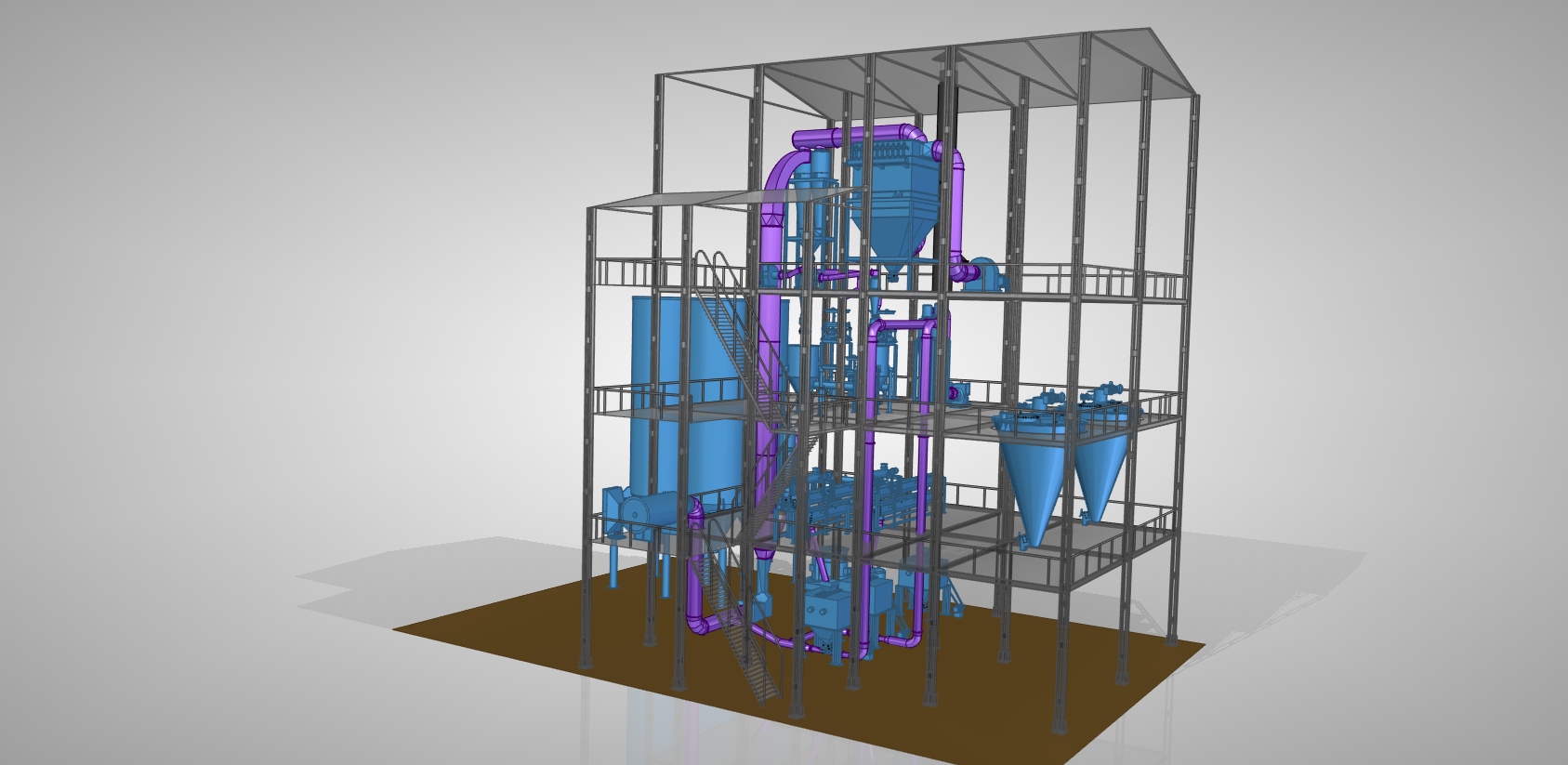

Guar Gum plant is used to obtain guar gum through a process that is configured and designed in such a way to get maximum end product using minimum heat and force. It is a complicated process and uses different machineries. Raj Process Equipment manufactures Guar Gum Plant in Pune. It not only designs the entire plant but also helps the client in installing it.

Equipments for guar gum processing

plant:

1. Raw Material Conveying

On a pneumatic conveyor system Guar

Gum Splits are moved through various

tubes via air pressure, allowing for extra

vertical versatility. This Pneumatic

conveyor is used to carry raw material to

raw material storage hopper for further

processing. The contact parts in Carbon

Steel.

2. Raw Material Storage

The material conveyed through pneumatic

conveying system is stored in Mild Steel

hoppers. Further it is conveyed to washing

system using control valves.

3. Washing Conveyor

Guar splits are screened to clean and then

soaked to pre-hydrate in washing conveyor.

Pre-hydrating stage is very important in the

process as it derives the rate of hydration

of the final product.

The soaking and conveying of guar splits is

totally depends upon the design and

manufacturing of hydration conveyor. So it

plays very important role in production of

high viscous guar gum powder.

Raj Process can manufacture single, two,

three, four deck hydration conveyors as per

Different machines which are part of Guar Gum Plant

- Pneumatic Conveying System

- Storage Silo

- Hydration System

- Grinding Equipment

- Flash Dryer

- Ribbon Blenders

- Steam Boiler

- Process Water Tanks

Raj Process Equipment manufactures affordable Guar Gum Plant in Pune which can be easily installed. They handle the entire project from design to installation and also provide after-sales service and maintenance.

Features

- Fully automatic system to ensure smooth and easy operation.

- Sterile construction of equipment to maintain high hygiene level.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- Complete sanitary design with CIP system.

- PLC controlled SCADA operated system.

Services

- Turnkey Plants.

- Manufacturing and Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management services.

- Commissioning and Training.

- After Sales Support.