Plough Shear Mixer

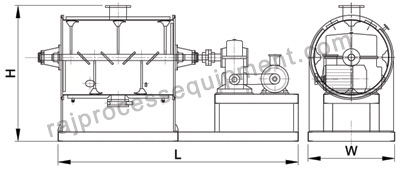

Raj plough shear mixer is a horizontal mixer with cylindrical drum and horizontally installed mixing shaft. The mixer is designed for heavy duty blending of both dry and wet material. Plough shape shovels mounted on a central shaft with its sharp ends easily penetrate through the dense powder and thick pasty mass. Extra shear can be attained by adding side mounted choppers.

Design features of plough shear mixer :

|

|

Typical applications include homogenous mixing of pastes, rubber, heavy plastic mass, food, pharmaceutical, chemicals etc.

RAJ Plough Shear mixer is a horizontal mixing system with horizontal, cylindrical drum and horizontally installed mixing shaft .

RAJ Plough Shear Mixer is designed for heavy duty blending of both dry and wet materials. Plough shape shovels mounted on a central shaft with its pointed ends are easily penetrable through the dense powder, pasty mass.

The overlapping of shovels coupled with its shape and the high speed of the ploughs produces good mixing action and high turbulence.

The arrangement of mixing tools is the result of many years of development by RAJ process equipments combined with experience based on mixing trials and practical scientific work.

RAJ Plough Mixers are high energy, high shear, and high-speed mixers with cylindrical short aspect ratio mixing chambers. Extra shear can be achieved by adding side cutters or intensifiers. The use of high speed choppers further reduce the product particle size thus resulting in a better mix.

RAJ Plough Mixers are available with 'Easy Clean' cantilevered shaft, subject to application.

Applications

- Quick and homogenous mixing of pastes, rubber, and heavy plastic masses.

- Bulk Powder in dry / dry solids, dry / wet paste, and wet-wet mass.

- Applications in Food, Pharmaceutical and Chemical industries.

- Solid Solid Mixing.

- Solid Liquid Mixing.

- Homogenizing.

- Blending.

- Granulation.

- Multiple Phase

- Reactions.

- Drying.

- Carbon Paste Mixing.

Features

- Hygienic design.

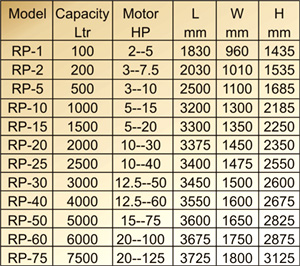

- Available in working capacities of few Liters to few thousand Liters.

- Custom built to suit customer requirements.

- Available in Stainless Steel and all grades of Carbon Steel.

- Optional Teflon Coated Internals for Food and Sticky material applications.

- Alternative trough shapes are available to suit specific application requirements.

- Optional wear resistant liner plates provided for abrasive products.

- Jacketed construction available for steam and cooling applications.

- Can be offered for vacuum application.

- Rapid mix times.

- High-energy mixes.

Choppers are working in conjunction with the shovels, intensify the mixing process. They are used for dispersing lumps which are either in the original product or which forms during process, they chop pasty additives or prevent the formation of agglomeration when liquid is introduced to the mix.

The number and type of choppers which are installed is governed by the size of the mixer and the purpose for which it is used.

Type of choppers are available for highly specialised mixing process.

Types of choppers offered :

- Multiple choppers.

- Tulip choppers.

- Shearing segment choppers.

- Turbo choppers.

Features

- Fully automatic system to ensure smooth and easy operation.

- Sterile construction of equipment to maintain high hygiene level.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- Complete sanitary design with CIP system.

- PLC controlled SCADA operated system.

Services

- Turnkey Plants.

- Manufacturing & Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management.

- Commissioning and Training.