Tomato Processing Plants in Pune, India

Tomato puree, sauce, ketchup and powdre plant

Millions of tones of tomatoes are grown each year and pass to the user in various forms like paste, ketchup, powder etc. The tomato processing plant is used to process raw tomatoes and convert them into puree, ketchup, sauce, and powder. It not only processed the tomatoes but also has an option for cleaning and sorting bad tomatoes. The process ensures that only quality tomatoes are used in making finest tomato ketchup, puree, and sauce. Raj Process Equipment is known to provide the world-class tomato processing plants in Pune India.

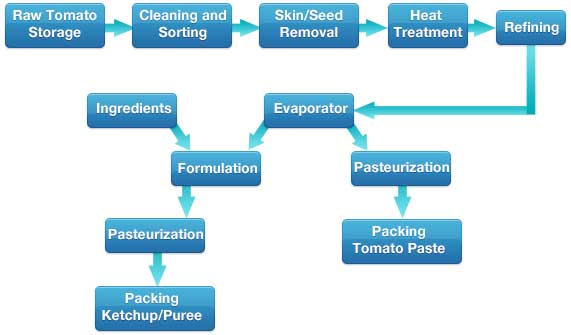

Process flow diagram for tomato processing plant

Process flow diagram for tomato powder

Features of the Tomatoes Processing Plant

- Fully automated system to ensure smooth functioning

- Sterile construction of equipment to maintain an optimum level of hygiene

- Optimal utilization of space through smart designing of the types of equipment

- Intelligently selected construction material keeping in mind the product propertie

- The energy-efficient unit so as to reduce costs

- Major types of equipment involved are tomato juice extractor, receiving tank, transfer pump, pulp preheater, Pulp storage cum balance tank, etc.

Services Offered along with product

- Sturdy manufacturing and timely supply of types of equipment

- Proper guidance is provided in civil and structural work required for installation

- Excellent after-sales support is provided for the smooth functioning of plant

Fresh ripe tomatoes are conveyed to washing vat and after washing the tomato are sorted on sorting section. The bad tomatoes are separated and further are broken. There are two methods of doing this namely "hot break" and "cold break". In hot break process, the tomatoes are quickly preheated before breaking, where as in cold break the tomatoes are broken at room temperature and kept in holding tank for some time. The skin and seeds are carefully removed and are refined. The juice is then concentrated with the help of evaporator. Further the concentrated pulp has converted to variety of the product like ketchup, puree or paste as per requirement.

The concentrated pulp is spray dried to get tomato powder and packed.

Raj Process Equipment supplies this equipment to not only many parts of India but also across the globe. If you are planning to enter the tomato processing business then you must choose Raj Process equipment as your business partner to ensure your success.

Features

- Fully automatic system to ensure smooth and easy operation.

- Sterile construction of equipment to maintain high hygiene level.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- Complete sanitary design with CIP system.

- PLC controlled SCADA operated system.

Services

- Turnkey Plants.

- Manufacturing and Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management services.

- Commissioning and Training.

- After Sales Support.