Ribbon Blender Mixer Manufacturer India

Ribbon Blender Mixer is used across various industries for the manufacture of

dry powder, talcum powder, spices, granules, low-viscosity paste, etc. It is extensively

used in industries like pharmaceuticals, chemicals, food, and cosmetics.

Ribbon Blender is ideal for products like pharmaceutical materials,

insecticides, pesticides, food material, etc which require handling of largely dry and wet

volume and that too could be heat sensitive. Ribbon Mixer is a result of the smart use of

advanced technology to accomplish fine quality blending and is considered one of the most

efficient machines of the world.

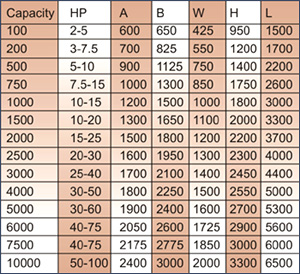

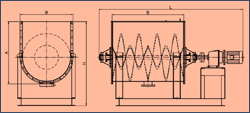

Raj Ribbon Blenders are available from Lab model to Heavy duty model. Ribbon

Blender is a light duty blender, useful for easy mixing powder components it is a LOW SHEAR

Mixer, most commonly used for SOLID/SOLID, SOLID/LIQUID Mixing and when high shearing force

is not required. Its counter flow helicoid flight mounted on shaft ensuring gentle mixing.

Blades are designed for triple action mixing to suit product end

characteristics. It also occupies less head room space for large volume mixing.

Raj Process Equipments manufacture all kind of Ribbon Blenders and Mixers which

vary from Lab models to Heavy-duty blenders. They are one of the best Ribbon Blender Mixer

Manufacturer in India.

|

Features of RAJ Ribbon Blender

and Mixer

|

|

Options Available

- Single shaft design for Low to Medium\ volume capacity.

- Double shaft design for Large to Mega volume capacity.

- Discharge butter fly valve.

- Discharge side gate valve.

- Jacketed ribbon blender design for a process that required heating and cooling.

- Vacuum capability to effect the removal of moisture accomplishing DRYING and MIXING in single operation.

- 4-B finish available.

Application

- Mixing of cosmetic powders.

- Dry mixing of free flowing powders requiring low shearing force.

- Dry blending of capsule formulation.

- Lubrication of dry granules in large quantity.

Raj Ribbon Blender and Mixer are designed to give the best results to the clients. They occupy less space and give a maximum return for the client’s money.

Features

- Fully automatic system to ensure smooth and easy operation.

- Sterile construction of equipment to maintain high hygiene level.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- Complete sanitary design with CIP system.

- PLC controlled SCADA operated system.

Services

- Turnkey Plants.

- Manufacturing & Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management.

- Commissioning and Training.