Salt Processing Plant:

Salt is the common name for the substance sodium chloride (NaCI), which occurs

in the form of transparent cubic crystals.

In industry salt with its converted forms such as chlorine, caustic, soda ash are being used

in various industries such as petrochemical refining, petro chemistry, organic synthesis ,

bulk drug and pharmaceutical industries.

In consideration of edible salt it should be processed hygienically so as to make it

consumable for human being, which raises the need of suitable refining process of salt to

meet today's demands such as its purity, color, crystalline nature, particle size

distribution and free flowing behavior.

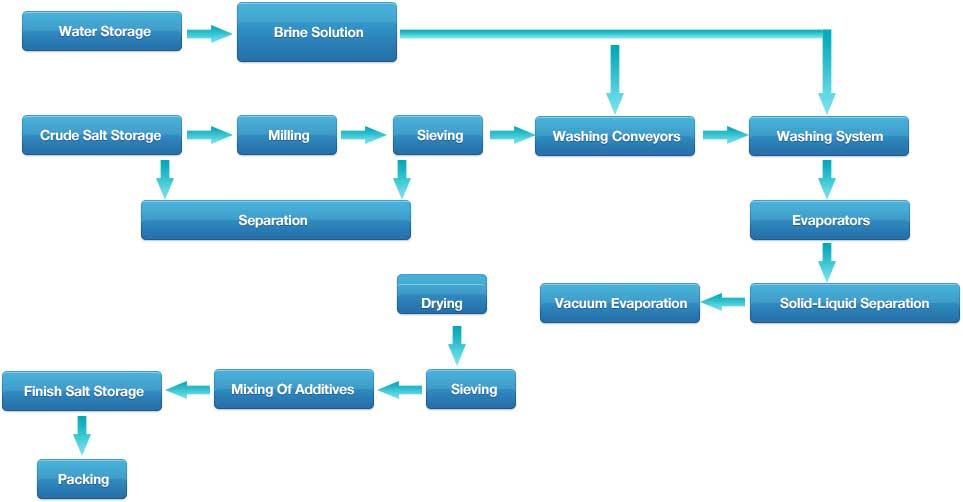

Process Description

Crude salt from the source is collected in large storage vessels from where the salt is

conveyed for grinding it to fines and segregated through a mechanical sieve. Crude salt is

then pre-washed and mixed with water in suitable form to form brine solution. Crude Salt is

fed through a volumetric belt Feeder for size reduction in presence of brine solution and

fed to washing system. Many impurities categorized to soluble and insoluble in water are

gathered in washing system which effects in the removal of soluble and insoluble by

flotation from slurry formed in washing system. Make up fresh water is fed at various points

of the washing system to keep soluble in permissible limit.

From washing system concentrated slurry is fed to the evaporation system consisting of multi

effect evaporators. Water is evaporated from brine using steam-powered multiple-effect or

electric-powered vapor recompression evaporators.

To achieve the economy of operation, evaporator is operated under vacuum to reduce steam

consumption. This increases energy efficiency in the multiple-effect system.

Vapor recompression forced-circulation evaporators consist of crystallizer vessel, vapor

compressor and vapor scrubber. As the brine enters in crystallizer vessel, salt cake is

precipitated out from crystallizer. Vapor is withdrawn, scrubbed, and compressed for further

reuse.

The crystallized salt is sent to centrifuge where it is dewatered. There will be formation

of cake which will be sent to drier to form crystals of salts.

Features

- Fully automatic system to ensure smooth and easy operation.

- Energy Efficient.

- Optimal space requirement.

- Carefully selected material of constructions taking into account the product properties.

- PLC controlled SCADA operated system

Services

- Turnkey Plants.

- Manufacturing and Supply of Equipments.

- Engineering and Supervision of Civil and Structural work.

- Process and Detailed Engineering.

- Project Management.

- Commissioning and Training.

- After Sales Support.